Metal Triangular Roof Ridge Cap Roll Forming Machinery

Basic Info

Model No.: KYT40-21

Product Description

Metal Triangular Roof Ridge Cap Roll Forming Machinery

The metal triangular roof ridge cap roll forming machinery includes manual decoiler , main forming machine , hydraulic system , PLC control system , Cutting system and output table . It works automatically which is controlled by the computer .You can use the machine directly once you get it . No need to buy any spare parts .

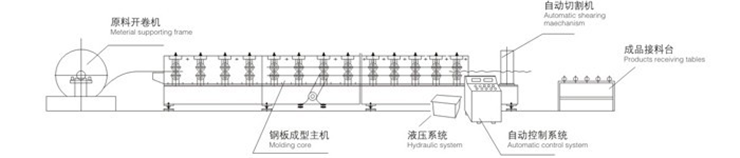

1. Ridge Cap Tile Process Flow

Decoiler- Feeding and Leveling device- Main Roll Forming System- PLC Control System- Hydraulic Cutting device- Discharge table.

2. Machine Parameter

2.1 Raw Material

A. Suitable Material: Colored Steel Plate, Galvanized Board, Aluminum Plate;

B. Width of the raw material: 500mm; C. Thickness: 0.3mm - 0.7mm;

2.2 Main Body

A. Roller station: 11 Stations; B. Diameter of shaft: ¢66mm, 45# steel;

C. Roller material: 45# steel; D. Frame: 350 H steel;

E. Operate: Manual and Automatic; F. Working speed: 8-10 m/min;

G. Size (L*W*H): about 5800*1550*1510 mm;

2.3 Power

A. Motor power: 3 Kw, Hydraulic power: 3 Kw;

B. Voltage: 380V 50Hz 3Phases or Customization;

C. Driving way: By Chain

3. Components of machine

3.1 Manual Deciler

Frame Structure: H-beam and Steel plate seamless welding.

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 1.5T; Inner diameter: 450-508mm;

3.2 Feeding Table

Feeding Table: It is used to control the width and position of the steel sheet. The sheet is guided into the machine with correct position, to make sure the panel is neat and parallel.

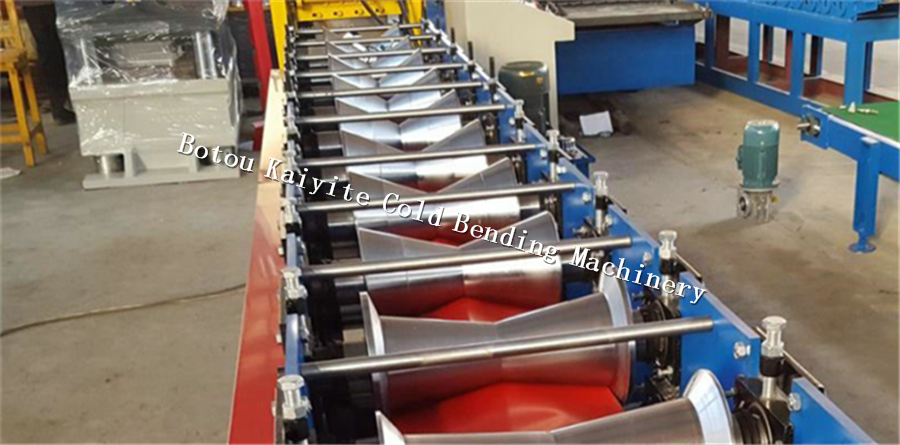

3.3 Main roll forming system

In order to keep the product shape and precision, adopts welded sheet structure, moter reducer drive, chain transmission, roller surfaces polishing, hard plating. The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

3.4 Hydraulic system

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraaulic pipes and two sets of electromagnetism vaves.

Hydraulic oil: 40#; Power: 3kw.

3.5 PLC Control Cabinet

We can do the automatic operation on the text screen to control the productional length and quantity. And with the frequency changer and back function, the line can guarantee the accurate counting.

Computed mode has two modes: Automatic and Manual one.

The system is easy to operate and use.

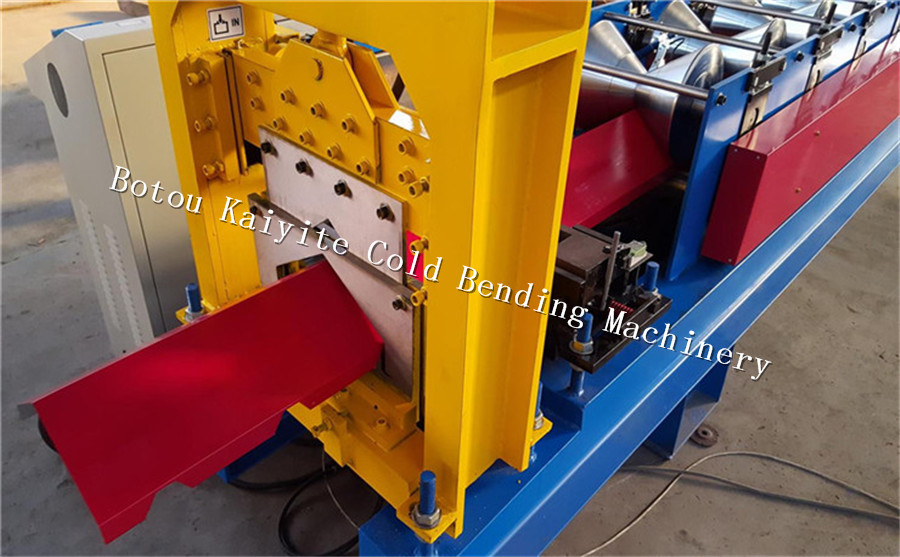

3.6 Hydraulic Cutting Device

It adopts hydraulic driving and Automatic location system to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment;

Length Cutting Tolerance: 10m±1.0mm

3.7 Discharge table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

There are two frams with the length of 3m/piece.

3.8 Spare Part

One box for free.

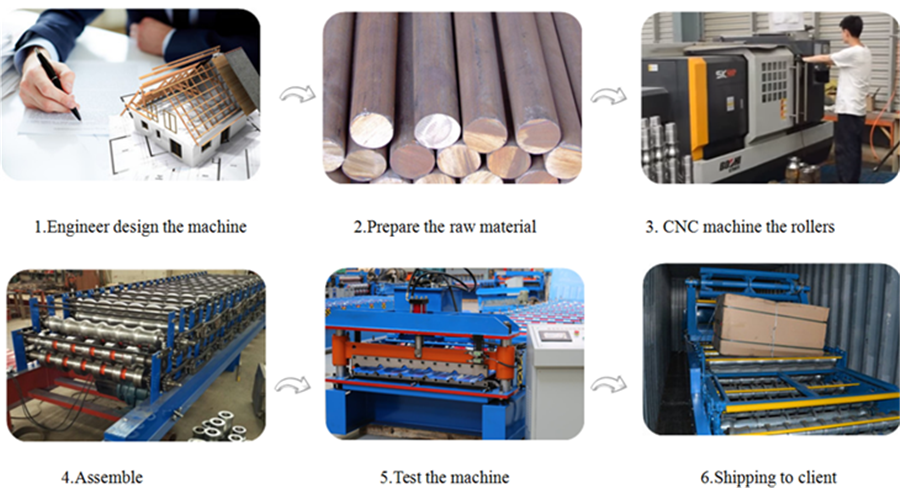

4. Production Process

The following picture shows the whole production process of the roll forming machine.

5. Packing and Shipping

For this machine need 1*40 GP container to load, one container can load 2 sets machines normally.

Before loading to container, we will check and test machine frist.

Second, make some protection on the machine. Such as, we will make the plastic package on the easy damage parts, paint the oil on the roller and shaft, in case the roller and shaft got corrosion and rusty during long time delievery.

Third, we will fix all the parts into container by steel wire rope. And ensure the machine will not damage when shaking on sea.

At last, we will take phoots and videos for customer when loading to container, so that the customer can take out the machine easily when receive the goods.

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including roller shutter door roll forming machine ,door frame machine, roof and wall panel roll forming machine , double layer roll forming machine ,floor deck roll forming machine ,C / Z / U Purlin Roll Forming Machine , stud and track roll forming machine , ridge cap roll forming machine , downspout pipe roll forming machine , shearing machine and bending machine , slitting and cutting machine .

6. Contact Information

Product Categories : Ridge Cap Roll Forming Machine > Roof Ridge Cap Roll Forming Machine